Forklift Load Rollers

Product Overview

Load Rollers are used in the mast of a lift truck to guide the mast interlocking channels when raising and lowering forks. The Load Roller, as the name implies, carries the load as the mast channels move up and down.

The design and quality of the load roller, affects not only the structural capacity of the mast and carriage assembly, but also its functional characteristics such as smooth operation, noise, and channel wear.

Fact: The most common cause of mast load roller bearing failure is miscellaneous impacts (the mast or carriage bumping into storage racks or loads).

Key Performance Indicator #1

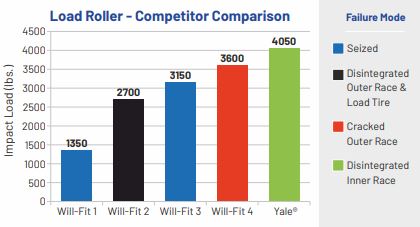

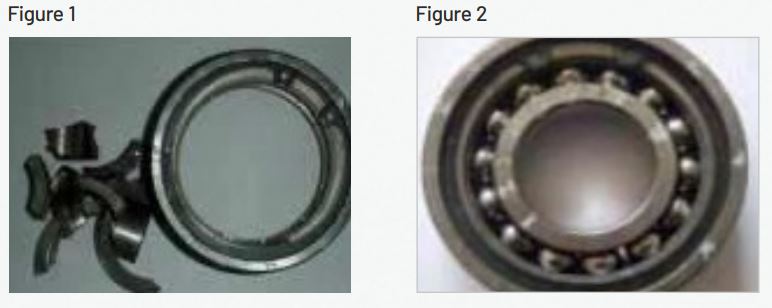

Yale® Load Rollers are manufactured from high grade bearing steel. The bearing components and the tyre are both heat treated, tested, and designed to ensure long life, integrity, and maximum performance of the mast and carriage assembly. Recent impact testing of the Yale® Load Roller versus four Will-Fit brands (see test chart and figures 1 & 2 below) indicates the Yale® Load Rollers are as much as three times more resistant to failure due to impacts!

Fact: If the ball bearings have been improperly heat treated, they will deteriorate and may result in the bearing seizing

After standard impact testing, one Will-Fit load roller shattered completely (Fig. 1), while another completely seized (Fig. 2).

Key Performance Indicator #2

Yale® Load Rollers have been designed to have the maximum number of ball bearings between the inner and outer race. This allows the load to be distributed over a larger area, which reduces contact stress, improves impact resistance and extends the service life of the bearing.

Key Performance Indicator #3

Yale® Load Rollers are permanently lubed and sealed in order to prevent corrosion and contamination from affecting smooth operation and/or reducing the life of the bearing.

Key Performance Indicator #4

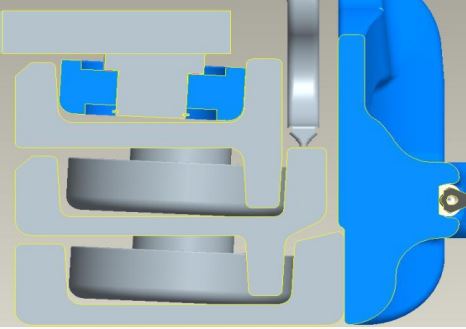

Yale® mast and carriage design utilises a 3° mounting angle to minimise galling and provide smooth roller contact with both the flange and web sections of the mast channel.

For proper operation, the load roller must be machined with the correct radius and relief contours in the outer tyre that match the mast channel section configurations. It must also have the inner race profile machined correctly to provide both radial and side thrust loading required by the 3° mounting.

Conclusion

Before purchasing Will-Fit load rollers, ask your supplier the following questions to better understand the quality of the load roller they may want to supply you:

- Does the bearing you are considering have the same amount of ball bearings as the Yale® Load Roller?

- What is the thickness of inner and outer races of the bearings?

- Are the inside and outside dimensions correct?

Chances are, if you are paying for a cheap bearing, then that is what you are getting. Why take the chance on Will-Fit parts that can lead to expensive repairs, excessive truck downtime, and reflect poorly on the Yale® brand of lift trucks?

Expert aftersales support for

Disclaimer

© Copyright 2020 | All the names and logos used here are the registered trademarks of respective companies. For private circulation only. Certain data mentioned here is based on assumptions and theoretical calculations, hence may not be accurate in practice and can’t be considered as a claim by the company.