Project challenges

The Sohar plant of L&T was using 2 nos. of 200/50t DG EOT cranes in one of its manufacturing bays for handling heavy components and fabricated structures. They wanted to relocate these cranes from the Sohar plant to their manufacturing facility at Hazira in India. The Hazira plant is one of the largest heavy engineering plants in the world where cranes of various manufacturers including ElectroMech are being used.

The relocation of these cranes from the Sohar to Hazira plant was planned to further boost the handling capacity of Hazira plant to meet growing production requirements. The entire project was challenging for several reasons such as

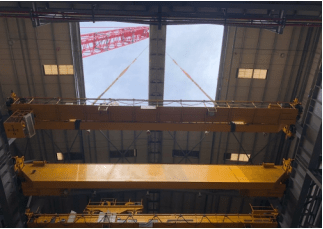

- The two cranes, each with a capacity of 200/50t and span of 23.6m, are extremely heavy, being of old design

- Each crane with around 25m long girders weighs about 25t

- Both the cranes had been installed at 25m height and taking them down was indeed a challenge

- The entire crane dismantling was to be completed in just 15 days, that too, without affecting regular production in the plant

- The cranes were to be re-erected safely and commissioned at the Hazira plant in India

Solution from Cranedge

Considering the mammoth size and weight of each crane, the L&T team was anxious about the feasibility of taking down the cranes safely without halting their regular work in the same plant.

However, the Cranedge team, with its expertise of providing solutions for such critical challenges, suggested an easy way out. The idea of temporarily opening the roof was put forth by the Cranedge team. This would allow a crawler crane to handle large and heavy parts from outside just by lowering the hook from the opened roof without actually entering the shop floor.

With this idea, the Cranedge team developed a complete project schedule to meet the deadline stipulated by L&T.

The job was well done at Oman with proper packing and marking of components so as to make the re-erection easier. L&T undertook the responsibility of shipping the crane to the Hazira plant.

Once it reached there, the Cranedge team re-erected the crane and commissioned it, within just 15 days.

The L&T team is extremely happy with Cranedge’s professional work and for completing the project well before the deadlines, while adhering to the highest safety standards.

The work of dismantling the cranes in Oman was handled through our associate company in Dubai – ElectroMech FZE. The erection & commissioning in the Hazira plant was handled by the Cranedge team in India.

L&T Heavy Engineering LLC is a Joint Venture between the L&T Group and the Zubair Corporation located at Sohar, Oman. Operational since 2009, this is the first Heavy Engineering facility of L&T Group outside India and is equipped to manufacture critical equipment for refineries, petrochemicals, fertilizers and other process industries.

Spread over 300,000 sq.m., Sohar Works has executed complex projects with a spectrum of metallurgies for renowned customers worldwide, and is ably supported by an infrastructure that covers 13,200 sq.m. under covered area with overhead cranes capable of lifting 500t. An open fabrication yard of 120,000 sq.m. is available for manufacturing of large-sized vessels. The facility

is fully equipped with state-of-the-art machines.

Benefits to L&T Heavy Engineering LLC

- Efficient use of existing assets for increasing productivity

- Phenomenal cost saving involved in procuring new cranes for the Hazira plant

- Strict adherence to timeline by ElectroMech and Cranedge teams in spite of a short notice helped in saving huge shipment costs. (The cranes were shipped from Oman with other machinery that was going to Hazira.)

Expert aftersales support for

Disclaimer

© Copyright 2020 | All the names and logos used here are the registered trademarks of respective companies. For private circulation only. Certain data mentioned here is based on assumptions and theoretical calculations, hence may not be accurate in practice and can’t be considered as a claim by the company.