Project challenges

Shortly before the summer of 2010, Cranedge received a request from BSL, who needed an allencompassing solution to erect and commission two used cranes that had been procured by them. The Cranedge team immediately visited the shipyard and conducted a preliminary audit of the stored cranes, procured from Swan Hunter. The equipment, which included seven cranes, had been in storage for ten months and initially, BSL required Cranedge to refurbish and erect two 55/10.10t Morris make EOT cranes.

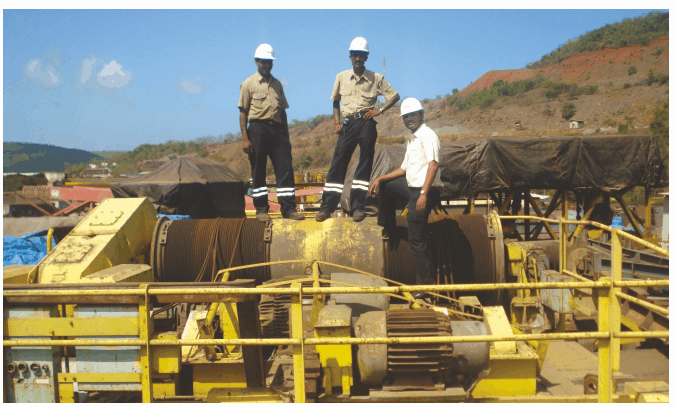

As a first step towards erecting these cranes, Team Cranedge proposed to undertake a detailed health check-up of the cranes, constituting an inspection of the mechanical and electrical assemblies. The inspection and health check-up of the cranes was conducted over a seven-day period and the Cranedge team submitted a report, along with an offer for the overhauling and replacement of components.

Bharati Shipyard Ltd. (BSL) is the foremost privately operated shipyard in terms of shipbuilding facilities in India. BSL has earned a stellar reputation by constructing a large array of specialised sophisticated vessels for the diverse offshore, coastal and marine market sectors. Bharati has four operating shipyards – Goa, Ratnagiri, Ghodbunder near Mumbai, and Kolkata.

Bharati Shipyard Ltd., set up a greenfield project at Dabhol, spread over 300 acres of land on the banks of the river Vashishti. The shipyard is designed by First Marine International of UK and has the capacity to build, among other vessels, jack-up drill rigs, offshore structures and ships upto 100,000 DWT. For this, BSL had purchased a shipbuilding yard from Swan Hunter (NE) Ltd., Newcastle, UK, with all equipment in as-is-where-is condition and moved it to their new site at Dabhol.

Swan Hunter (NE) Ltd. is a renowned shipbuilder in Europe, existing since 1880. The yard is now owned by the North Tyneside Council and shipbuilding activities have ceased there. However, Swan Hunter continues to provide engineering, design and management support to the shipbuilding and offshore industry.

Scope of work

- DG EOT Crane – 2 nos. 55/10/10t, 30m span, 23m height of lift Make: Herbert’s MORRIS, England (Year 1969)

Complete overhauling, assembly, erection, commissioning, and electrical circuit modifications were carried out as per our logic - DG EOT Crane – 1 no. 30t, 30m span, 23m height of lift Make: Carruther, England (Year 1969) Complete overhauling, assembly, erection & commissioning

- DG EOT Crane – 1 no. 10t, 29m span, 21m height of lift Make: Carruther, England (Year 1969) Complete overhauling, assembly, erection & commissioning

- DG EOT Crane – 1 no 10t, 29m span, 21m height of lift Make: Demag (Year 1982) Complete overhauling, assembly, erection & commissioning

- Deck Cranes on Floating Dock – 6t and 8t Supply of CRD with CRD cable, installation at site and commissioning

Solution from Cranedge

The report recommended cleaning, servicing and lubrication of all the major components, such as gearboxes and motors of both cranes. Electricals and the electrical panel were to be refurbished and several components such as limit switches, crane cable trolley and crane wire rope, which were either damaged or missing, were to be replaced. In addition to these corrective measures, the report also suggested upgrading features such as gravity limit switches, radio remote controls and anti-collision devices of the cranes. BSL entrusted Cranedge with the supply of all parts and spares required to bring the cranes into operational readiness.

Once the initial order had been executed to BSL’s satisfaction, they engaged Cranedge to refurbish the remaining five cranes

Benefits to Bharati Shipyard

- Efficient reuse of assets at minimum investment

- Significant saving in capex involved in procuring new cranes

- Time saved in procuring new cranes

Expert aftersales support for

Disclaimer

© Copyright 2020 | All the names and logos used here are the registered trademarks of respective companies. For private circulation only. Certain data mentioned here is based on assumptions and theoretical calculations, hence may not be accurate in practice and can’t be considered as a claim by the company.