Replacing the worn out wheel of your forklift with ‘any’ other wheel may lead to repeated equipment failure and increased downtime!

Background

A leading company in the Indian FMCG sector has a large warehouse in Bengaluru in Karnataka state. The company is using 20 nos. of Yale reach trucks to manage the handling activities at their warehouse. The reach trucks were being maintained by in-house maintenance team

Being one of the major warehouses of the company in south India, this warehouse experiences a large number of transactions every day. This calls for massive movement of material and, in turn, the reach trucks are used extensively.

Challenges

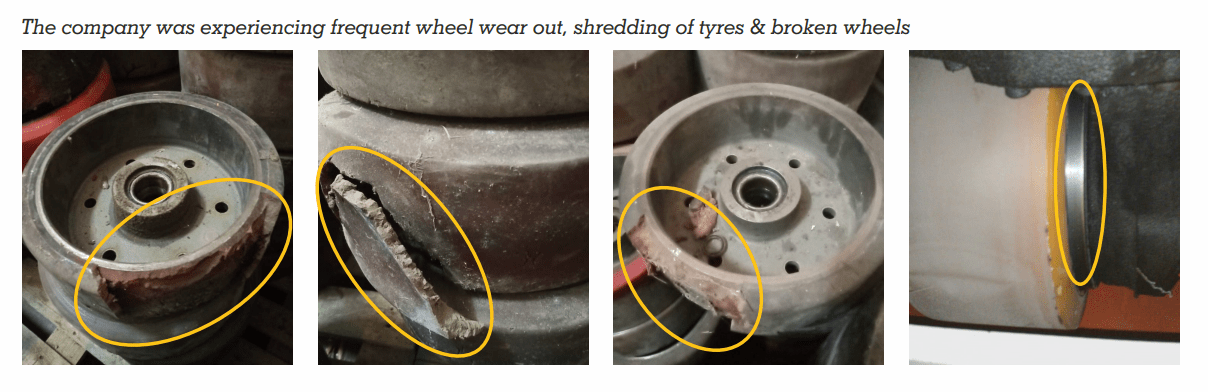

As a result of the long distances travelled by the reach truck, for excessive material movement, their wheels frequently wore out. As a quick solution, the procurement team of the company hired a local supplier of such wheels which also reduced operational costs.

However, their inferior quality of the wheels resulted in either fast wearing out of the tyres or frequent debonding of the tyre from the wheel rim. Once the PU bonding wore out or debonded from the rim, it required to be changed. This resulted in frequent replacement of wheels due to which the equipment remained stationary. The impact was two-fold.

The first was that although the wheels purchased were cheaper than the original spares, their life was short and hence the number of wheels required was high.

The second impact, which was more worrisome, was that equipment downtime was increasing. Equipment remained stationary until the time, worn out wheel was replaced. This was considerably affecting equipment availability, delivery schedules and the overall productivity of the warehouse.

Solution from Cranedge

The company approached Cranedge, service arm of ElectroMech Yale, for a solution to improve equipment uptime and productivity. Our trained service engineers visited the warehouse and inspected the equipment thoroughly. From the records, it was evident that the time lost in wheel procuring and changing was the major factor in equipment downtime. Further, when the wheels were inspected, we came to know that locally procured wheels were being used.

Immediately, our team fitted original Yale wheels on one equipment for conducting thorough trials. The results surprised the company and they were convinced about using original spares, even for simple parts. A complete cost-benefit analysis clearly revealed that equipment availability can be drastically improved with a marginally higher investment in buying original spares.

The company not only replaced the wheels of all the equipment with the original Yale wheels, but was also satisfied with our service and approach, and awarded us the AMC for the entire fleet of reach trucks and BOPTs.

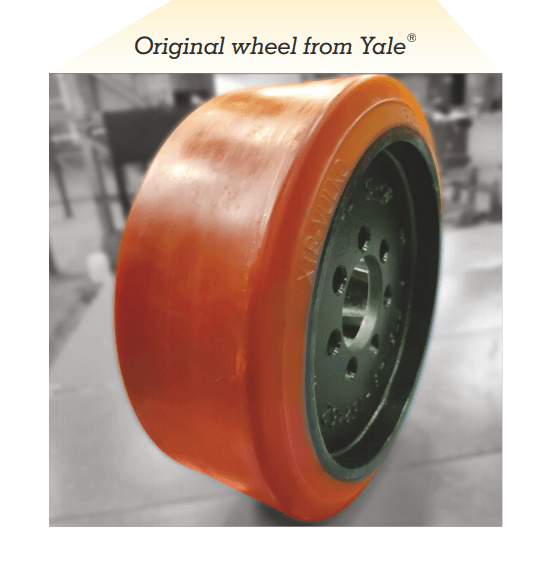

Benefits of using original Yale spares

- Reduced equipment downtime

- Increased productivity

- Lesser manpower required for maintenance work

- Reduced cost of operations

- Reduced inventory

Expert aftersales support for

Disclaimer

© Copyright 2020 | All the names and logos used here are the registered trademarks of respective companies. For private circulation only. Certain data mentioned here is based on assumptions and theoretical calculations, hence may not be accurate in practice and can’t be considered as a claim by the company.